Cable & Harness

Overview

Industry Leading Cable and Harness Services

- Build to print

- Application engineering to generate BOM and prototype cables and drawings

- LRIP capability with over 1700 hand tools in stock, NPI dedicated manufacturing center

- High Mix – Low Volume capability with over 350 benches and programmable benchtop equipment

- High Volume capability with 10 fully automatic cut, strip, mark and crimp centers

- Extensive equipment capability and open capacity to produce these products

High Speed Data

Coax

Molded

Harness

Power

Cable Box Build

Cable Box Build

Cable & Harness

Experts on C4ISR Cable Assemblies From Concept to Production

i3 Assembly has performed work for the following platforms:

- Perform DFM to industry and workmanship standards

- FBCB2, BFT and JBC-P. MFoCS system supplier

- Providing vehicle system cables on M-ATV platform (WIN-T)

- VIC intercom systems ( VIC-3 and VIS-X)

- Integration cables for EPLR, Rifleman Radio, SINCGARS, PRC117, PRC152, PRC154, TL3300, SIR, and many other soldier communication systems

- CREW 2.0,2.1 3.2& 3.3 IED systems cables including antenna

- RWS Remote Weapon System

- Active Protection systems performed all drawing development

- E/O Infrared System cables

- Laser Targeting systems CLRF, JETS

- NATO power system connectors and cables

- Nett Warrior- soldier warn HUB and cables-in line electronics in cables

- Spider mortar launch system

- DVE driver vision enhancement

Certified Instructors

Our internal training capability allows i3 to grow significantly with our certified training system for IPC-620.

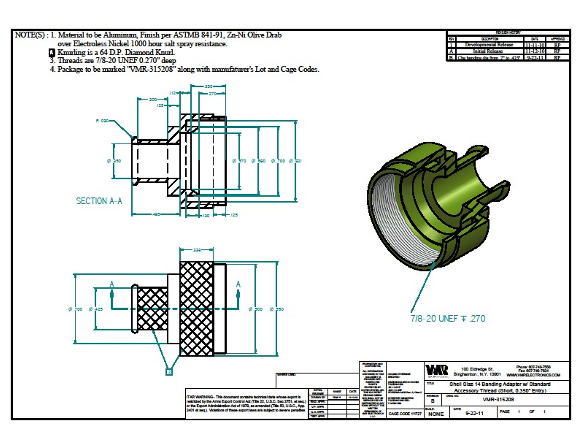

DFM – Cost Savings

i3 has the ability to make back shells, provides quick turn and custom size to fit the application.

Provides cost savings and improved delivery

i3 performed and co-authored the changes to workmanship/ BOM specifications for 160 different cables.

The Prior (left) solution has boots, back shells and requires higher labor. The New (right) solution has an Integral Backshell part of connector and mold

i3 Engineering solved a problem for a cable melting. The Prior (left) cable was a commercial circuit breaker. The New (right) solution added an EMI filter into cable with a new inductor and ruggedized cable and circuit breaker.

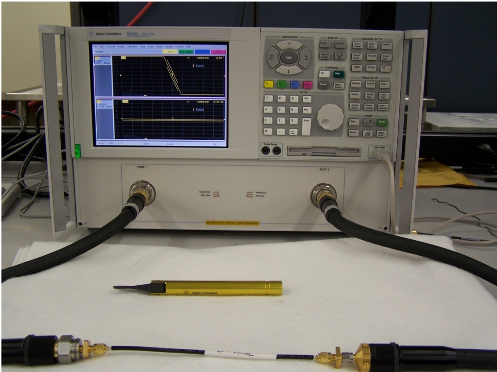

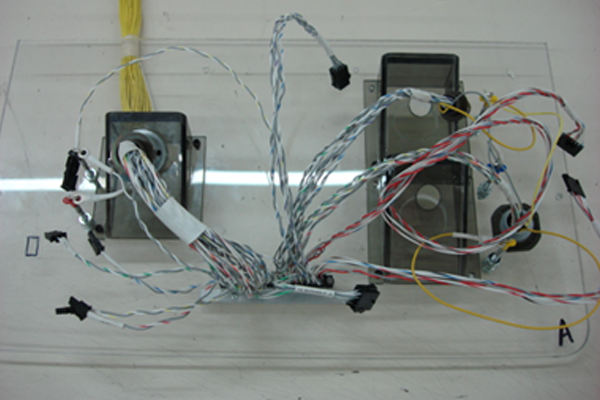

Test

- VSWR & Insertion Loss

- Phase Matching

- Pull/Testing (Crimp/Solder) Dielectric

- Withstanding Voltage HiPot testing (1500V)

- 4 Wire Ohm Measurement USB Signal Integrity

- Power Supply Functional Test Audio Testing

- Low DC Resistance Testing Fiber Optic OTDR

- Fiber Optic DORC Interferometer Measures Angles and Surface Roughness

- Capacitance Resistors Tektronix TDR

- 3D Laser Measuring System

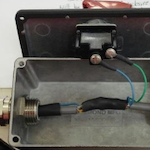

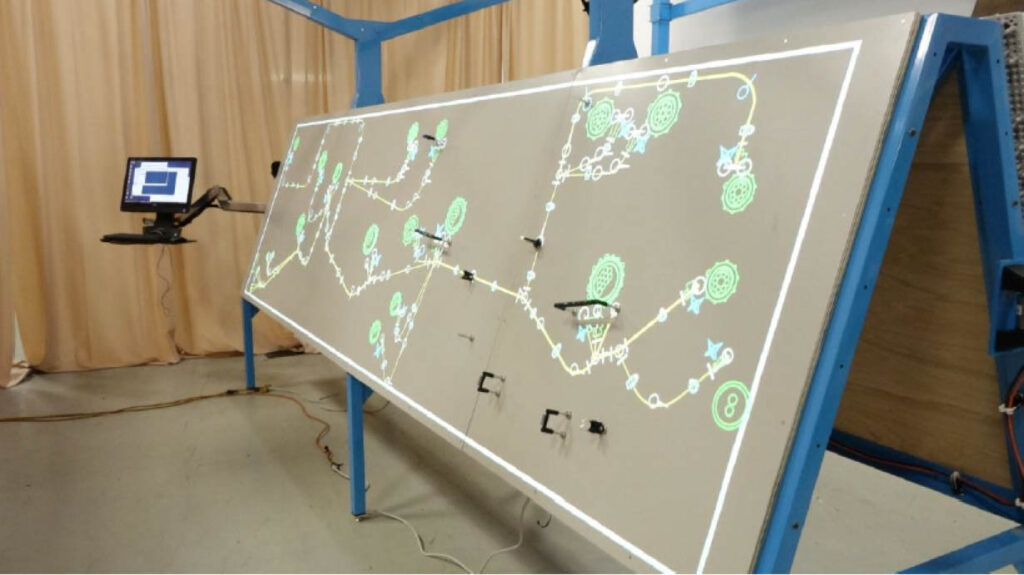

i3 builds our own Test mate boxes (above)

Test – Submergence

Submergence testing is performed at an AQL level defined by customer requirements/spec. This test method is used to verify the process of sealing the boot to the jacket and boot to the backshell.

i3 suggests an AQL of .65. Chart describes the lot size and the frequency of the check.

First Article Inspection

i3 Has a Proven History of Supporting Over 200 First Articles Per AS9102 (most current revision) Per Month for Over a One Year Period.

FAI’s focus not only on the end product but are also developed for detailed in-process inspection. In-process inspection planning is developed independently.

All critical dimensions are highlighted and captured within the program. Once captured and saved, the program will create a PDF Ballooned print.

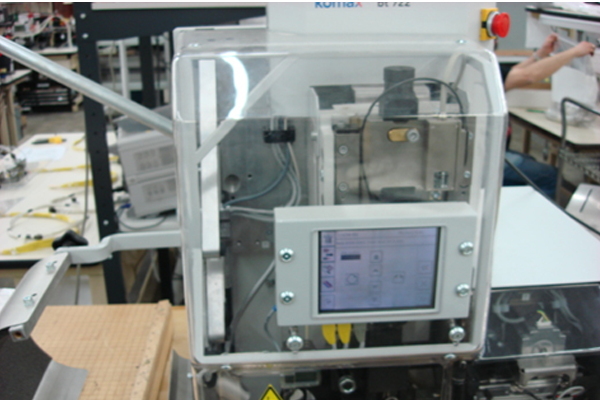

High Speed Data

i3 PCB assembly lines located next to our cable assembly manufacturing, offers very competitive pricing with quick turn capability for the integration of PCB’s into cable assemblies.

Phase match over 100’ long

Cat6 Across many platforms

D38999 Quadrax

i3 manufactured housing with switch and 4 I/O connectors

USB converter board to Serial with switch over molded

USB Repeater Board in cable

Key Equipment

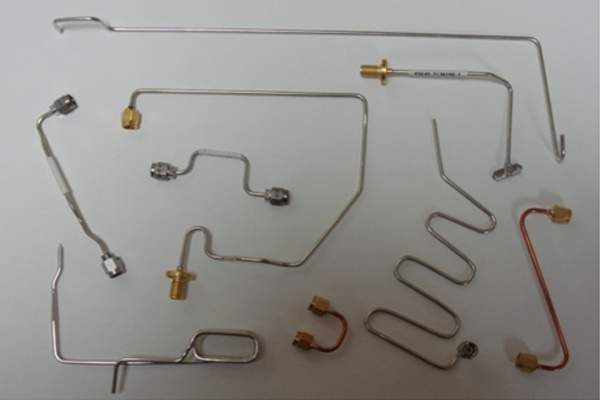

Coax

Products:

Semi-Rigid

Flexible cables

Conformable

Iditarod ® i3 Patented

Antenna Cables

We provide phase matching capability for all types of Coax.

2 coax phased match +/- 1°built over 25,000 pcs

Typical internal coax – high volume capability

Highly automated to produce large quantities of long antenna cables LMR style shown here

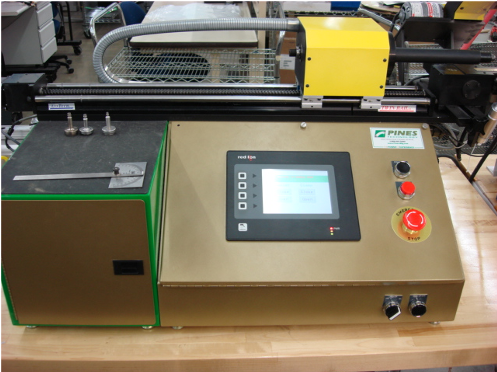

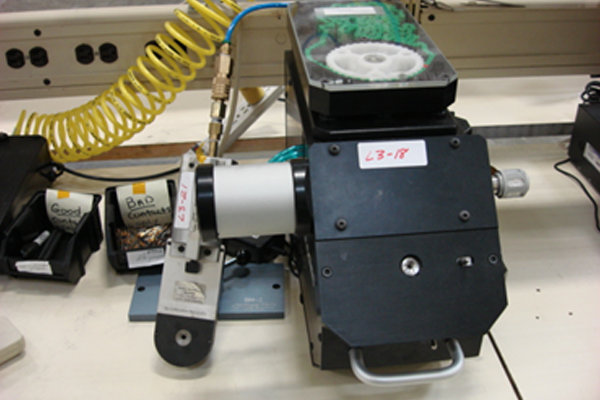

Programmable bending fully tested with network analyzers to 66 GHz, all types of connectors .086”, .140” and .250”

Programmable bending fully tested with network analyzers to 66 GHz, all types of connectors .086”, .140” and .250”

Coax Equipment

Molded Cables

Mold Equipment

EPDM, Neoprene, Viton, Rubber Mold Presses

Mold Capability for low pressure over PCB’s and coax

High Pressure injection mold for Viton, EPDM, Neoprene

Polyurethane injection mold machines

i3 designs and manufactures most of our tooling and fixtures within our internal machine shop

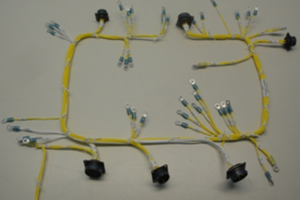

Harness

Harness Equipment

Power

Power Equipment

Large amount of hydraulic and pneumatic crimp tools for large gauge lugs and terminals.

High volume automated large power cable (up to 1.38” diameter) to cut, slit, strip, label and coil.

Military Ruggedized Circular Connector

Labels

We Utilize All Types of Labels In the Industry

Mil-STD 130 UID, Heat shrink Thermal transfer, Hot Stamped, Wraptor labels, and laser marked tags.

We also utilize all types of marking’s for cable jackets, 4 laser markers, ink marking and hot stamp in line marking machine types.

Brady TMS marker, Brady Heat shrink marker and cutter (Sumitomo type) 4 Brady Wraptor label maker some in line. Dot Matrix printer.

We perform AQL level testing of part mark permanency in the label production area to Mil-M-81531.